Serving the worldwide community of radio-electronic homebrewers. Providing blog support to the SolderSmoke podcast: http://soldersmoke.com

Podcasting since 2005! Listen to our latest pocast here:

Podcasting since 2005! Listen to Latest SolderSmoke

Monday, June 2, 2014

El Peregrino (The Pilgrim) from Spain

Eduardo, EA3GHS, sent this to me. It looks like a wonderful bilateral SSB rig for 17 meters.

They said they wanted a "daylight" rig (for a daytime band) because in Spain the religious pilgrims walk all day and are tired at night. Hence 17 for Los Peregrinos!

http://ea3ghs.qrp.cat/peregrino.html

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Sunday, June 1, 2014

Alan Wolke's GREAT Video on Transmission Line Termination

An outSTANDING Wave video from Alan! Check out the comments from new hams on the YouTube page: Alan has a real knack (!) for explaining technical material, and for imparting real understanding.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Saturday, May 31, 2014

Harv's Minima

Good Evening Bill & fellow Solder-smoke friends,

Well, I’m following the pack. I began gathering items for the Minima Transceiver back in March 14. There had been a good bit of strong back-N-forth discussions on the Minima Blog about what works and what doesn’t work. Some circuit refinements had been agreed upon while other were left to individual preferences. So, I decided to just be silent an learn from the experts. As a result, I did several months of observing before I took the plunge. While my efforts are not nearly as aggressive as others, I decided to forge a much slower path to success.

In my own quirky way of doing things, I kitted each module, measured all the parts statically, laid out the components, and finally built & tested each assembly before going to the next.

As a result, the learning’s were great and the performance of each section equal or better than my expectations.

I went the Manhattan Style this time but, I have purchased several sets of Minima PCBs to use in the future. As I see it, there is a lot more solder melting ahead.

Bill, building radios is NOT DEAD yet. That desire to get back to the golden days of home-brewing still lives on.

At the end of the Memorial Weekend, this is my current Minima progress…

· Construction of all 3 Audio Stages now complete (see photos)

· The Microphone Pre-Amp is now awaiting voice testing

· Audio Amplifier and Final Amplifier have been tested together

· The results of audio testing has been superb for all stages thus far

· 3 complete sets of Micro Relays have been order and I’m now awaiting their arrival

· 24 – various ferrite and powered iron cores arrived several weeks ago, these are the heart of the front-end RX/TX stages

· 100 - 20 Mhz. crystals have arrived and await characterization

· 25 - 8” Male to Male SMA Cables have arrived this weekend, will need to order 15 – 4” Male to Male SMA Cable Assemblies next

· 5 – 12” X 15” Copper Clad Boards have arrived this weekend

· 25 –J310 N-channel J RF Power FETs were ordered and arrived this weekend, these are used in the Mixer Stage

Final Audio Stage

Audio Amplifier Stage

Microphone Pre-Amplifier Stage (see microphone connector mounted at rear)

I’m ready to begin kitting the Side Tone Oscillator and RX/TX Relay Stages.

The largest and most intense modules are yet to be tackled.

The Bi-Directional Amplifier has 34 parts alone. So far I have installed over 40 parts in the three modules I’ve completed…

I realize it is just a start but, I’m motivated to see this one project through to completion.

73’s & Happy Soldering

Harv -=WA3EIB=-

Albuquerque, NM.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Friday, May 30, 2014

Contact Reestablished with ISEE-3 Satellite

http://spacecollege.org/isee3/we-are-now-in-command-of-the-isee-3-spacecraft.html

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Monday, May 26, 2014

SolderSmoke Podcast #161: Homebrew SSB: An Interview with Pete Juliano, N6QW

http://soldersmoke.com/soldersmoke161.mp3

26 May 2013

Homebrew Single Sideband -- An Interview with Pete Juliano, N6QW

-- Pete's background: 55 years in radio. Boatanchors AND Arduinos. 40673 Mosfets. Guitar!

-- A personal transition from CW to phone.

-- The importance of passing on "tribal knowledge."

-- What you need: A library, tools, test gear and a junque box.

-- A new word in the homebrew lexicon: Pete explains "noodling."

-- One stage at a time!

-- The attractiveness of standard circuit blocks (that work!)

-- The importance of IF selection.

-- Building your own crystal filters is easier than ever.

-- Thinking (early) about the enclosure.

--VFOs, VXOs, and (gasp) Direct Digital Synthesis

Thanks Pete!

Pete's Web Site: http://www.jessystems.com/

Pete's YouTube Channel:

https://www.youtube.com/channel/UC4_ft4-oTdCMlWlL4XXHScg/videos

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Friday, May 23, 2014

Meteor Shower Tonight

If the skies are clear, and if I can stay awake, I'll be out there looking for the new meteor shower.

But there is no real need to go outside. David, EA1FAQ has an SDR receiver tuned to a radar frequency in France. You can see and hear the meteors as they create a path for the RF. Very cool.

Thanks David:

http://www.ustream.tv/channel/live-meteor-radar

You can also listen for meteor pings here:

http://spaceweatherradio.com/

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

But there is no real need to go outside. David, EA1FAQ has an SDR receiver tuned to a radar frequency in France. You can see and hear the meteors as they create a path for the RF. Very cool.

Thanks David:

http://www.ustream.tv/channel/live-meteor-radar

You can also listen for meteor pings here:

http://spaceweatherradio.com/

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Wednesday, May 21, 2014

Overheard at Dayton: Drake 2B Market Manipulation! (& Help needed with 455 kc IF can)

I received a very nice message from Preston Douglas. Conveniently, he is an attorney, and I have asked him to stand ready to defend me in court should I ever be accused of manipulating the markets for Drake 2-Bs (and perhaps the market for SSDRAs).

Can any out there help Preston with his SX-110 455 kc IF can?

May 20 at 3:38 PM

Hi Bill,

I enjoyed #160, even though I heard those talks, live at FDIM.

I thought you'd be amused by what I overheard in the flea market on Saturday in Dayton. I was looking at a Drake 2B and Q multiplier being offered by a lady who said they were her father's. They looked to be in pretty clean shape, though of course there was no way to know what was going on under the hood. She was asking $200 for both, and said she was open to reasonable offers. Now, I already have a 2B and haven't found any need for the Q multiplier. And I had flown out to Dayton from NY, so would have had to ship the pair of boxes home--probably should have bought them anyway and sent them home by UPS for that kind of money.

Anyway, there were two other guys looking at the 2B. One said to the other that these were among the best receivers of the tube era, but that the prices had become inflated by this guy who does the Soldersmoke podcasts talking up the virtues of the 2B. Couldn't help smiling at that.

As to the Hallicrafters SX-110 on the repair bench. Well, I worked out a deal with a professional tech guy to trade him my non-working HP 8640b sig gen for some bench time on the 110. He found that the first IF transformer that I was having so much trouble aligning was non-working. He had no replacement, so he bypassed the whole transformer with a cap to get signal to the next stage. This is, of course, not a satisfactory solution. And nobody has that IF can to sell. I did read on another radio repair guy's web site that he, too, usually stops working on a set with a bad IF can because repair is so labor intensive.

Frankly, I don't accept that. I mean what's inside there? A couple of coils and some open silvered mica leafs. So, I plan to remove the can, open it, and fix it. According to the Internet, the built-in caps on these cans become defective and need replacement by modern capacitors. Or, maybe a wire is broken off. Before I do anything, I am going to see if that transformer is really unable to peak at 455. Anyway, maybe I'll get some time to mess with this radio over the holiday weekend.

One of the guys (or was it you?) recently said he builds 'em, makes a few contacts to prove they work, and then puts them on a shelf. Then he builds another one. It's like that sometimes.

PRESTON DOUGLAS

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Tuesday, May 20, 2014

Latest Project: 17 Meter Moxon

17 Meter Moxon by AE6AC

That's what I have in mind. I ordered four fiberglass "crappie" poles yesterday. I have a tripod for the roof. What should I use to spin this thing around? A TV rotor is an obvious solution, but the last time I used one it didn't hold up too well. There is always the Armstrong method...

Here's AE6AC's site:

http://www.moxonantennaproject.com/ae6ac/ae6ac.htm

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Saturday, May 17, 2014

SolderSmoke Podcast 160: Special Four Days in May (FDIM) issue

George Dobbs, G3RJV

SolderSmoke Podcast #160:

http://soldersmoke.com/soldersmoke160.mp3

Bob Crane, W8SX, was out at the Four Days in May event and did an excellent series of interviews with the guys who made presentations:

Many Ways To Homebrew

Battery Powered Software Radios:

Having your cake and eating it, too

The Classic World of the Regenerative Receiver

Why Does My Rig Have a Receive Antenna Jack ?

The Great Arduino, JT65 and Rebels Caper

High adventure with new radio paradigms

PoW QRP

-------------------------------------

VIDEOS OF THE PRESENTATIONS ARE HERE:

http://www.ustream.tv/recorded/47599691

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Tuesday, May 13, 2014

Message in a Bottle -- Beacon in a Bottle

Wow. Very cool. Don't get hung up on the legalities or the environmental consequences. Just enjoy the simplicity and the technique. All the details are on this very nice Italian site. Google will translate it for you, but the pictures and the schematic tell most of the story. Bravi!

http://air-radiorama.blogspot.it/

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Saturday, May 10, 2014

FDIM Midnight Mojo Ceremony (Tuna Tin 2)

Tyson Tuna Tin Two

An important message From Rex,

Transcendental Titan of the Tuna Tin Twos:

--------------------

Fans of the Ancient Sacred Relic,

If you have a little QRP rebel in you, like me, and are a fan of Ancient Sacred Relic, i.e. The Original Tuna Tin 2 transmitter, and all things housed in round metal containers usually designed for fish products and pineapple, and maybe cats if VERY thoroughly cleaned, then you might want to bring your Tuna Tin 2 rig to FDIM!

Around midnight, after the scrum leaves the FDIM Club night gathering, there will be a Tuna Tin 2 Midnight MOJO ceremony! THE one and only ORIGINAL Tuna Tin 2 transmitter will be on hand for this solemn occasion where major QRP MOJO is transferred from the Ancient Sacred Relic into the tuna can inductees in attendance. Admission is free but you MUST bring a MOJOee tuna can housed rig for entrance to the ritual.

NO rectangular or mint tin equipment will be admitted!! NO unaccompanied minors OR adults OR adults who act like minors will be admitted.

TT2 QRP MOJO will be transferred....FUN will be had.....PRIZES will be raffled off!

If you think you might like to be there for the Tuna Tin 2 Midnight MOJO ceremony remember to pack a tuna can or reasonable facimile (307 (3 + 07/16" diameter) industry standard 2 piece or 3 piece can) housed TT2 style rig in your travel bag!!

REMEMBER: NO rectangular or mint tin equipment will be admitted!! You must have a TT2 inspired rig in you personal possession to gain

admittance! NO exceptions!!

Respectfully submitted,

Rex W1REX The TUNA Tinman!

--------------------

If you have a little QRP rebel in you, like me, and are a fan of Ancient Sacred Relic, i.e. The Original Tuna Tin 2 transmitter, and all things housed in round metal containers usually designed for fish products and pineapple, and maybe cats if VERY thoroughly cleaned, then you might want to bring your Tuna Tin 2 rig to FDIM!

Around midnight, after the scrum leaves the FDIM Club night gathering, there will be a Tuna Tin 2 Midnight MOJO ceremony! THE one and only ORIGINAL Tuna Tin 2 transmitter will be on hand for this solemn occasion where major QRP MOJO is transferred from the Ancient Sacred Relic into the tuna can inductees in attendance. Admission is free but you MUST bring a MOJOee tuna can housed rig for entrance to the ritual.

NO rectangular or mint tin equipment will be admitted!! NO unaccompanied minors OR adults OR adults who act like minors will be admitted.

TT2 QRP MOJO will be transferred....FUN will be had.....PRIZES will be raffled off!

If you think you might like to be there for the Tuna Tin 2 Midnight MOJO ceremony remember to pack a tuna can or reasonable facimile (307 (3 + 07/16" diameter) industry standard 2 piece or 3 piece can) housed TT2 style rig in your travel bag!!

REMEMBER: NO rectangular or mint tin equipment will be admitted!! You must have a TT2 inspired rig in you personal possession to gain

admittance! NO exceptions!!

Respectfully submitted,

Rex W1REX The TUNA Tinman!

--------------------

I will not be at Dayton, but I might be able to lend my TT2 (seen above with Tyson) should some worthy radio amateur wish to participate in the midnight ritual. Time is short, so if you are interested, send me an e-mail explaining why you are worthy.

Friday, May 9, 2014

HOMEBREW ETCHANT!

http://hackaday.com/2014/05/08/testing-the-efficiency-of-pcb-etchants/

This is great. We can add this to the list of kitchen and household products useful in our kind of projects! Desitin for heatsink compound! Breadboards for breadboards! Now this!

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Wednesday, May 7, 2014

Parts Cost for BITX in India: $5 US (that's buying all the parts!)

I knew that in India you could build a BITX for a few bucks, but I thought that this cost estimate assumed a fairly well-stocked junk box. Not true! This morning an e-mail from Farhan points out that even if an Indian ham has to BUY all the parts, he can get all of them for the equivalent of 5 dollars U.S.:

"Less than half a cent per resistor, less than a cent per capacitor, two cents per npn transistor and 50 cents for the IRF510. We use 'tv baluns' and tap washers for coils."

And, from the original BITX design page:

"The purpose is to address the need among Indian hams in particular for an SSB rig that is easily and cheaply built. My original aim was to keep the price under Rs. 1000. The current design brings the cost to well under Rs.300 (less than 7 dollars)."

Now, when you are talking to someone using a new $10,000 Yaesu/Icom/Kenwood rig, it might be a bit unkind to mention that your rig can be had for $5.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Saturday, May 3, 2014

The Guy who Invented the LED

I'm a big fan of Ira Flatow's "Science Friday" radio program (recommended!)

This week, while digging through the archives, I found this gem:

http://www.sciencefriday.com/segment/10/12/2012/fifty-years-ago-a-bright-idea.html

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

This week, while digging through the archives, I found this gem:

http://www.sciencefriday.com/segment/10/12/2012/fifty-years-ago-a-bright-idea.html

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Friday, May 2, 2014

Bert's EMRFD Direct Conversion Receiver

Very nice Bert. Sounds great. I like the pill bottle coil core. Lew McCoy used them in his designs. I do think that air core coils do provide better stability than ferrites or iron powder. I kind of like the SW broadcast background music. I also like the internal 9V battery. Glad to see someone else resurrecting an old DC RX project.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Thursday, May 1, 2014

VFO for BITX 20/40

Here's the VFO I use in my BITX 20/40. IF is obviously 11 MHz. VFO normally tunes 3697-3859 kHz for 40 meters. Switching in that 220 pf cap lowers the range to 3292-3189 kHz for 20 meters. It workd very well. The coil is wound on a cardboard tube from a coat hanger. I will put this in the appropriate file on the BITX group site. I like the 20/40 band combination: Good DX possibilities on 20, with provisions (40!) for the low sunspot counts to come.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Wednesday, April 30, 2014

Manhattan meets Hyderabad: Pad Pattern for my BITX 20/40

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Monday, April 28, 2014

Our New Robotic Overlords

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Friday, April 25, 2014

Homebrew Blimp with paper-thin Arduino (Printoo)

More on Printoo (very interesting!):

https://www.kickstarter.com/projects/1030661323/printoo-paper-thin-flexible-arduinotm-compatible-m

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Thursday, April 24, 2014

Hackers Recover 1960's Moon Pictures

http://www.wired.com/2014/04/lost-lunar-photos-recovered-by-great-feats-of-hackerdom-developed-at-a-mcdonalds/

Thanks to Mark, K6HX, for alerting me to this wonderful project.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Wednesday, April 23, 2014

Pete Juliano's Bilateral Rigs (with videos)

Hi Bill,

I was finally getting around to reading one of the recent SPRAT’s and saw a photo of your magnificent BITX17. Congratulations! A tip of the hat to Farhan for that very excellent design and it truly is a design that has traveled the world and made a radio available to many who otherwise would not be on the air.

It is a very robust design as I scratch built one in 2005 (or maybe 2006) and just for fun socketed every transistor so I could try various devices. I even had a bag of 2N706’s dating back to the late 1960’s. They all worked except for the carrier oscillator where I just couldn’t get enough swing in the oscillator to correctly place the CIO on the filter slope. That I attribute to the junction capacitance of the 2N706. By far the lowly 2N3904 that I bought for 4 cents each worked the best. Back when I built this I was W6JFR. Adding the EI9GQ frequency stabilizer really added a nice touch to the radio.

I should also tell you that when I built the radio my intent was to uses a piece of single sided copper vector board for the main chassis. It was the weekend and I didn’t realize the piece I had was not big enough for the project. So I took a piece of standard perf board and overlaid that on top of a piece of single sided copper PC board –AND hand drilled all of the holes – I went blind, cross-eyed and had a terrible hangover after consuming 6 beers in a short time span! See the photos below.

BTW I also built a 17M SSB transceiver using the bilateral amp stage from G4GXO as appeared in the SPRAT 128. That used a 4.9152 MHz IF and a 23 MHz Super VXO. In the case of the VXO I used 11.52 MHz crystals in the VXO and used a diode doubler to put the LO at 23 MHz. With the doubler –you get the bonus of 2X the frequency shift of the Super VXO. I also had made a custom set of crystals and used a small relay to switch those into the circuit and that essentially gave me almost the full SSB Band coverage. You can see that here

Also I have been using a simple bilateral stage consisting of a 2N3906 and 2N3904 and the results have been amazing. The latest work is a follow on to my shirt pocket transceiver and uses SMD components. See attached.

Here are some videos of the latest –which is now a two bander 40 and 20M. (Originally it was 75 and 40M)

https://www.youtube.com/watch?v=0UlBX7aznnM&list=UU4_ft4-oTdCMlWlL4XXHScg and https://www.youtube.com/watch?v=Wa5WiUZ9KoY

Have fun – this is such a wonderful hobby!

73’s

Pete N6QW

Monday, April 21, 2014

Clocks, CRTs, HV supplies: Eric has The Knack!

Nice interview by Jeri Ellsworth. This fellow definitely seems to have the Knack. At the end of the video he shows a high voltage supply that he is WEARING AROUND HIS NECK!

Here's Eric's site: http://tubetime.us/

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Sunday, April 20, 2014

A Worthy Cause: Help Save the ISEE-3 Spacecraft!

http://www.rockethub.com/projects/42228-isee-3-reboot-project-by-space-college-skycorp-and-spaceref

Here is an excerpt from the above website:

Our plan is simple: we intend to contact the ISEE-3 (International Sun-Earth Explorer) spacecraft, command it to fire its engine and enter an orbit near Earth, and then resume its original mission - a mission it began in 1978. ISEE-3 was rechristened as the International Comet Explorer (ICE). If we are successful it may also still be able to chase yet another comet.

Working in collaboration with NASA we have assembled a team of engineers, programmers, and scientists - and have a large radio telescope fully capable of contacting ISEE-3. If we are successful we intend to facilitate the sharing and interpretation of all of the new data ISEE-3 sends back via crowd sourcing.

Time is short. And this project is not without significant risks. We need your financial help. ISEE-3 must be contacted in the next month or so and it must complete its orbit change maneuvers no later than mid-June 2014. There is excitement ahead as well: part of the maneuvers will include a flyby of the Moon at an altitude of less than 50 km.

Our team members at Morehead State University, working with AMSAT-DL in Germany, have already detected the carrier signals from both of ISEE-3's transmitters. When the time comes, we will be using the large dish at Morehead State University to contact the spacecraft and give it commands.

Thanks to Dave, WA8JNM, for the heads up on this.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Tuesday, April 15, 2014

AA1TJ Crosses the Pond with 10 milliwatts

From a Facebook Post by Mike, AA1TJ:

Made 7 contacts with this tiny transceiver on 20m CW today with an RF output power of 10milliWatts. Five were stations in Georgia (GA QSO Party). The 6th was a regular QSO with a guy in Mississippi.

I answered a DX station calling CQ at 2230Z. Hearing nothing in response, I sent my call sign a half-dozen times anyway. More silence. As I was reaching for the knob to QSY he suddenly returned my call! ...Carlos, CT1BQH northeast of Lisbon, Portugal (that's him in the second photo). I was only 329 on his end but we kept it going for three minutes!

FYI: the transmitter (top circuit board) begins with a 3.58MHz ceramic resonator VXO (a 2N706 from the early 60's). That drives a push-push frequency doubler built around another 1960's-vintage, 2N2644 (obsolete stock from atop Mt. Mansfield, kindly given to me by Rich at Vermont Public Television). On receive, the 7MHz energy is routed via a DPDT relay (the orange rectangle) to the sub-harmonic (Polyakov) mixer located on the lower board. One stage of AF amplification is provided by a 2N333 that came off the GE assembly line in November of 1958. The DPDT relay is keyed directly. On transmit the 7MHz energy feeds a second push-push frequency doubler to produce 10mW at 14MHz (all spurs -35dBc, or less, with only the output resonator). The relay also switches the antenna between the transmitter and receiver.

Gosh, that was fun!

Gosh, that was fun!

CT1BQH

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Monday, April 14, 2014

Bert's Pititico (PY2OHH) Rig (Video)

Bravo Bert!

http://wf7ihomebrew.wordpress.com/2014/04/13/a-listen-on-40m-with-the-1-transistor-pititico/

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Sunday, April 13, 2014

DSB Transceiver with Only 3 Transistors

Wow. Looks like something Peter Parker would really like. This one was sent to me by Stephen, G7VFY. It comes from Japan:

http://www.cqpub.co.jp/hanbai/

From this book:-

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Friday, April 11, 2014

"That 70s Show": Steve "Snort Rosin" Smith Restores a 70's era Tuna Tin 2

Hi Bill,

Your recent stories about your TT-2 and original TT-2 "mojo transfer" prompted me to resurrect my TT-2 'resto' project.

The attached photos show my 70s era TT-2 obtained for $5 from a QRP-L member. This is how I received it and you can see that it's almost a duplicate copy of the original, complete with 'phenolic' substrate PC board material and hand-scrawled traces.

I have collected most of the components necessary to convert it to a look-alike of

By hand selecting the two transistors for max. power gain I hope to eek 300 mW out of the thing.

Anyway, hope you enjoy the shots and I'll send more when it's finished.

73.......Steve Smith WB6TNL

"Snort Rosin"

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Tuesday, April 8, 2014

PY2OHH's New Super-Minimalist (11 Component!) QRPp Transceiver

Wow! Check out the latest rig from PY2OHH, the Wizard of Sao Paulo,

http://py2ohh.w2c.com.br/trx/pititico/pititico.html

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Pete Friedrichs' Amazing Books, Projects, and Guests

H.P. "Pete" Friedrichs is the author of two books that belong on our book shelves: "Voice of the Crystal" and "Instruments of Amplification." http://www.hpfriedrichs.com/mybooks/mybooks.htm

This morning I got a nice e-mail from Pete. He's been listening to the podcast.

His e-mail caused me to revisit his web site. Lots of minimalist homebrew gold there!

Check out the collection of projects sent to Pete from all around the world by readers of his books:

http://www.hpfriedrichs.com/guestgallery/guestgallery.htm

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Sunday, April 6, 2014

QRPp Model Planes

Michael, AA1TJ, alerted me to this very interesting hobby. The video is really beautiful.

http://floatdocumentary.com/documentary

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Saturday, April 5, 2014

Parachutist's Helmet-Camera Images Falling Meteorite

Just because it is pretty cool. Also, we like parachutes, meteorites, and Norway.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Monday, March 31, 2014

SolderSmoke Podcast #159: Hamfests, Herring Aids, and Tuna Tins

SolderSmoke Podcast #159 is available.

http://soldersmoke.com/soldersmoke159.mp3April 1, 2014

Vienna Wireless Hamfest

BITX Talk

W1REX speaks

Tuna Tin 2 Mojo Transfer Ceremony

After 38 years -- finishing my Herring Aid 5 receiver

Feedback, Phasing Dots, Rotational Sense, and Oscillation (or not)

Motorboating (when you don't want to)

Building my Tuna Tin 2 with parts from W1REX

On the air with Tuna Tin and Herring Aid

More Minimalist Meanderings:

An (Almost) All Altoid Crystal Radio!

Tek 465 dies (again) :-(

MAILBAG

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Sunday, March 30, 2014

First Contact with Herring Aid 5 AND Tuna Tin 2

Ah, it was a good morning in the N2CQR shack! Last week I ran into fellow ham David Cowhig at work. I was regaling him with tales of Herring Aid and Tuna Tin derring-do. Oh the stations I had heard with the receiver! And the stations that I'd worked with the transmitter! Then David asked the question: "Yea, but have you worked anybody with the receiver paired up with the transmitter?" Uh, no. Not yet.

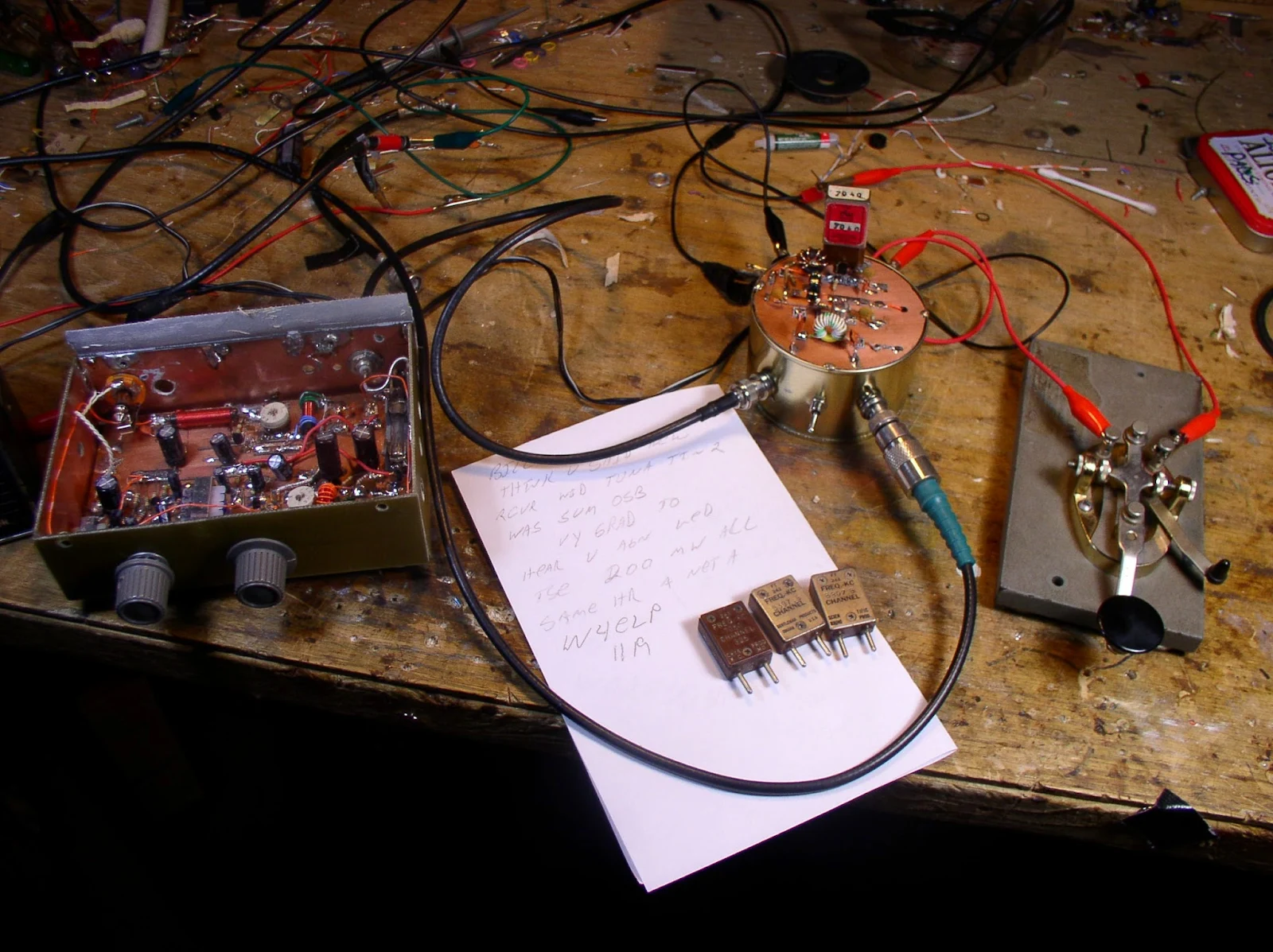

Well this morning I took care of that. 7040 kc. 1115 UTC. W4ELP was calling CQ. He wasn't too strong, and I wasn't sure if we were on the same side of zero beat (that's what happens with direct conversion -- you get all the sigs in two places on the dial) but I took a shot at it. And he heard me!

Here's the icing on the cake: This was his SECOND QSO with my Tuna Tin 2! Ed had been contact #4 when I was running the TT2 with the Drake 2B. After exchanging reports he asked "Bill ARE YOU STILL ON THE TUNA TIN?"

The rig (TX AND RX) is pictured above. Close-up of the receiver appears below. And below that is a picture of Ed, W4ELP, in his Georgia shack. Note the HW-8.

Thanks Ed! Thanks David!

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Saturday, March 29, 2014

Harv's DDS Function Generator

Nice looking DDS function generator Harv! Glad to see the HT-37 in the background. (And it appears well protected -- is that some sort of digital shielding to protect it from the bits and bytes?) The eraser buttons are a nice touch. Good luck with the Minima!

Hi Bill,

Well I have nearly completed my DDS Function Generator as I prepare to construct the Minima.

The Function Generator was a necessity for the bench so I can tackle Tweaking and Troubleshooting my work.

It is housed an aluminum box and completely self-contained.

My objective was to have the choice, to either lay the unit flat on the work surface or stand it on a shelf for easy reading while seated.

The Generator has both a DDS and HF-ECG output.

The buttons are fashioned from White Pencil Erasers since finding proper buttons for the membrane keypad beneath was difficult.

I have obtained a set of Farhan’s Boards for the Minima but will begin my effort with a Manhattan Style Construction so I can perfect my choice of parts.

The soldering iron is heating and I’m ready for a new and exciting challenge.

Happy Solder Melting Everyone!

Harv -=WA3EIB=-

Albq., NM.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Thursday, March 27, 2014

Remotely Controlled Stations on the Internet

Now for something completely different!

I find myself talking fairly often to hams who are using remote transceivers. The operator will be in say, Michigan, with the rig in Florida. Some of them are using the online system:

http://www.remotehams.com/

I signed up and downloaded the software. It works very well. Many of the stations are closed to outsiders, and some of them don't let you transmit, but it is fun to listen from remote locations.

This morning I hooked up the Tuna Tin 2 and was able to hear my 200 mW signal through AI4W's receiver in Kentucky.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

I find myself talking fairly often to hams who are using remote transceivers. The operator will be in say, Michigan, with the rig in Florida. Some of them are using the online system:

http://www.remotehams.com/

I signed up and downloaded the software. It works very well. Many of the stations are closed to outsiders, and some of them don't let you transmit, but it is fun to listen from remote locations.

This morning I hooked up the Tuna Tin 2 and was able to hear my 200 mW signal through AI4W's receiver in Kentucky.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Tuesday, March 25, 2014

Hackaday Goes to Shanghai

http://hackaday.com/2014/03/24/the-gathering-shanghais-hackaday-community/

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Sunday, March 23, 2014

VU2JN's "Transistor Transmitter from India"

VU2JN

VU2INJ's very interesting blog led me to a wonderful 1967 QST article by VU2JN. Check it out. Necessity truly is the mother of invention and -- as is the case with our beloved BITX -- we see that in the design of this transmitter. I love how the speaker was left in the cabinet and used as the microphone. Check it out:

http://vu3inj.blogspot.in/2014/01/tribute-to-vu2jn.html

More on VU2JN (who very clearly merits "Homebrew Hero" status):

http://shipwreck1.hopto.org:8080/projects/hamprojects/VU2JNArchive/

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Wednesday, March 19, 2014

The Really BIG Discovery (Cosmology, Gravity Waves, Inflation)

The signals that were announced this week are a bit outside our normal frequency range, but this is a REALLY BIG discovery so of course, it needs to be covered by SolderSmoke Daily News. I liked this info-graphic from space.com. It is worth looking at. Note the line "The universe continues infinitely outside Earth's Hubble volume."

http://www.space.com/25075-cosmic-inflation-universe-expansion-big-bang-infographic.html

Source SPACE.com: All about our solar system, outer space and exploration.

Source SPACE.com: All about our solar system, outer space and exploration.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

http://www.space.com/25075-cosmic-inflation-universe-expansion-big-bang-infographic.html

Source SPACE.com: All about our solar system, outer space and exploration.

Source SPACE.com: All about our solar system, outer space and exploration.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Monday, March 17, 2014

A Short Video on my Herring Aid 5

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

The Ladybird TRF (Regen!) Receiver

http://www.mds975.co.uk/Content/trfradios02.html

My feelings about regenerative receivers and their possible connections to the nether-world are well known. But the receiver described on this beautiful British web site is almost enough to make me change my mind. Thanks to Stephen, G7VFY, for alerting me to this (and to so many other great sites!) I also find myself forced to give regens another chance because George Dobbs, G3RJV, was the original source of this design. It comes from a book he wrote in 1972. I love the wooden bread-board construction. Thanks Stephen! Thanks George!

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Friday, March 14, 2014

The Wizard of Sao Paulo

It has been about 4 years since Miguel, PY2OHH, has been mentioned in this blog. That's too long! Miguel has churned out an impressive series of homebrew rigs, the latest of which he calls the Baita Tche. Does that name look familiar? It is a play on words using slang from Southern Brazil. "Baita" means big or enormous. "Tche" means "you." Together they sound sort of like BITX! Miguel has been building BITX rigs and rigs (like Baita Tche) similar to Farhan's rig. Here is his page on Baita Tche:

http://py2ohh.w2c.com.br/trx/baitatche/baitatche.html

Here is his home page with a LONG (almost JF1OZL-ish!) list of projects:

http://py2ohh.w2c.com.br/

Here's his YouTube channel:

http://www.youtube.com/user/py2ohh

Here's a Photostream of some excellent Brazilian homebrew:

http://www.flickr.com/photos/py2jcm/2066764415/in/photostream/

Muito obrigado Miguel!

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Farhan's RM386 RF Amplifier

An RF amplifier inspired by a quest for an AF replacement for the LM386. I like it! Check it out:

http://www.hfsignals.org/index.php/RF386

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

http://www.hfsignals.org/index.php/RF386

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Thursday, March 13, 2014

Herring Aid Motorboating STOPPED!

FIXED! Following up on suggestions from Tony Fishpool and from Roy Morgan, I put a 10 ohm resistor between the two supply lines and put 100 uF caps to ground at either end of the resistor. I can now operate the receiver at high AF gain (no problem running a speaker) without the KLUDGE of two power supplies. The RX sounds great. I will soon match it up with the equally awesome Tuna Tin 2 for 1976 QRP EXTRAVAGANZA.

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Stopping the AF oscillations in the Herring Aid 5

Thanks to all who responded. This morning I got a significant clue: Following up on Tony Fishpool's suggestion, I separated the power supplies: I ran the RF amp, oscillator and mixer base bias off a small 12 V battery, with the mixer collector circuit and the AF amps running of the bench 12V supply. The AF oscillations completely stop under these conditions. So the feedback is probably taking place via the 12 V supply lines. 73

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Our book: "SolderSmoke -- Global Adventures in Wireless Electronics" http://soldersmoke.com/book.htm Our coffee mugs, T-Shirts, bumper stickers: http://www.cafepress.com/SolderSmoke Our Book Store: http://astore.amazon.com/contracross-20

Subscribe to:

Comments (Atom)